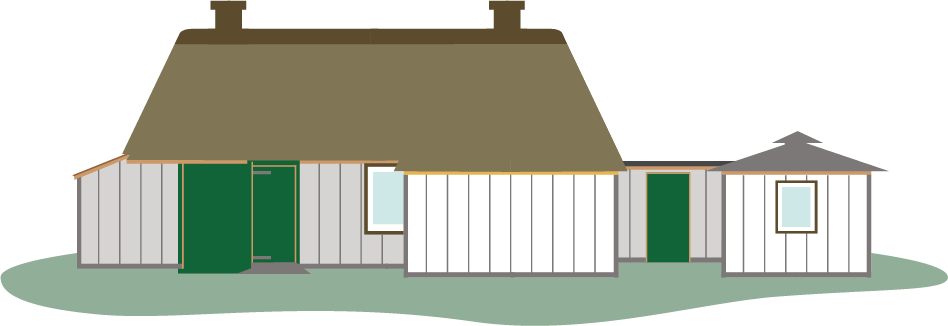

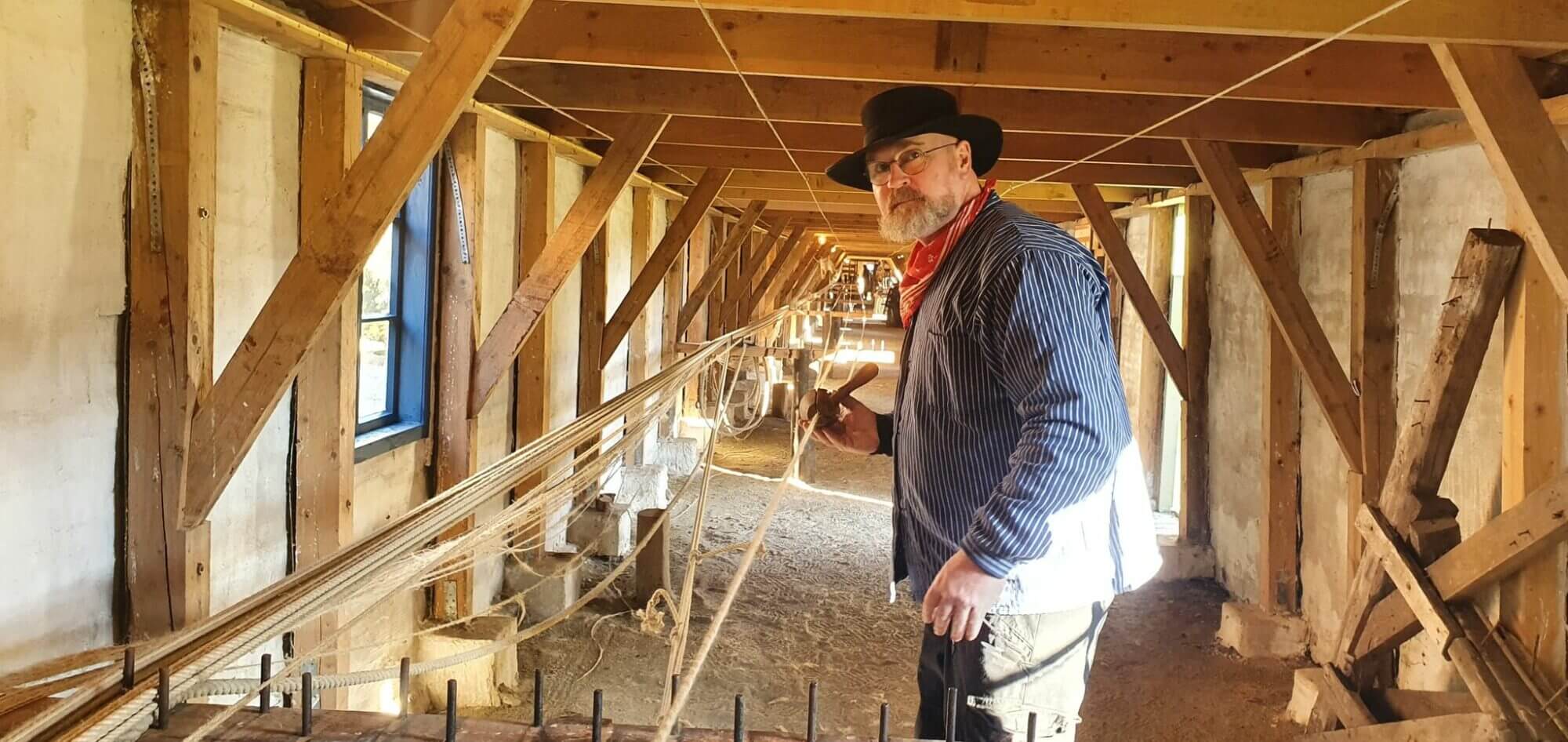

Rope slaughterhouse

The Reber track is 3.2m wide and 94m long. The section used in production is only 82m long. The first half dozen meters are used for storage and the hulling area. The hay loft is connected to the hemp spinning mill. When the hemp came home - typically in the spring - it had to be "through-harrowed". The fiber was beaten through with an oversized brush with large steel spikes. This released the hemp's euphoric substances, and when he had stood for a whole day in a cloud of dust from the hemp fibers, he had been "affected". Therefore, he always had to go home and take a nap before he could continue his day's work. This caused some amusement in the family that he was intoxicated without having touched a drop of alcohol - for he was missionary!

The working length of the course of 82m gives a finished length of 55m of rope or half a kvejl. A kvejl is a block of rope 110m long. If whole kvejl should have been made on the ropeway, the working length should have been 165m. For Jens Sahl Jensen's customer base, half that would have been enough. The ropes were sold by weight and not by thickness.

The shear has probably always been where we found it. There are five hooks on it and it is connected to an electric motor. It may well have been mounted with a hand crank, but since Skjern already had electricity in 1903, we can assume that the rope maker was one of the first to sign up. It still saved a day's wages in the production stage, and we have therefore chosen in our reconstruction to take the rope maker back to the time just after the introduction of electricity in Skjern, i.e. around 1905.

Remains of a large spinning wheel, which we guess to have been from the early period, have also been found. It is very damaged. Likewise, many other, different spinning wheels and cutters have been found on the ropeway, which will not be discussed here. There was almost nothing left of the stretching benches, in fact there was only a five-meter section. The rest we had to reconstruct from post holes, but then it was great that the post holes matched the calculations you can make on how much the rope shrinks when you wrap it together! At the aft end of the ropeway was the big stretching wheel. It has not been used since hemp production stopped, and it did so even before World War II.

The rope to be stretched was attached to another rope, which was wound onto a short, thick roller. This was connected by a shaft to a large belt wheel, which in turn was connected by a belt to an electric motor. The electric motor was not there, but the pulley for it has been found.

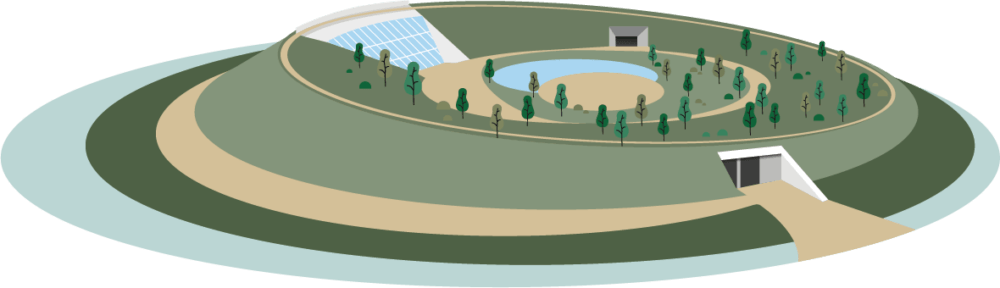

The automatic withholding tax was one of the first things we found. It gave us a lot of trouble. It consists of a thin roller and a thick roller in line with each other. From the thick roller, you have to coil almost 30m out onto the field, where it is held again at the end of the rope, as it gets shorter and shorter all the time during mowing. The thin roller hoists a weight from the ground and is wound up at the same time as the thick roller runs out. The low ground clearance of the Reber track left no room for the apparatus to finish mowing the square. During the excavation, we found a well at the rear end of the rebar track, which solved several problems. Firstly, the positioning of the apparatus, and secondly, it considerably increased the height of the plumb line's travel.

Many different items have been found, such as the "shears" that you use to twist the cords. The "top" (All sizes up to a two-inch braid and down to fine, thin laundry cords. Some are beautifully twisted and some are coarse - some are very worn and some are not yet used) gathers the cords into a rope. The "runner", (From simple runners made from bicycle wheel hubs to beautifully crafted brass runners.) is placed at the opposite end of the sheave - where it freely and without resistance runs out the cords coming from the sheave. The size of the runner is determined by the dimension of the rope. The many objects we found are a real treat for a rope maker and provided opportunities for exciting solutions in reconstructions.

The tarring of the finished ropes took place three-quarters of the way down the ropeway, where there is a small chimney hole in the wall. Here there was a small glue oven where the bucket of tar was heated to boiling point. The tar was then poured into an oblong trough and the rope was pulled through the bath, or the bucket was taken along the rope and the tar was painted on. This was done inside the ropeway itself, which was not particularly exciting. You can taste the tar many days later.

Sahl

During World War II, the ropeway boomed. The son H.P. Sahl advertised for riprap for brooms. A piece of handmade rope has been found. Either it is just a sample or it is a piece of "ironing rope", intended to smooth the finished rope. The technique used can be traced back far into Norse antiquity.

A different use of the reberbanen was as a weapons depot for resistance fighters. The track is said to have been used to deposit weapons for the resistance movement. It is certain that shots were fired at the back wall, but the size of the caliber is doubtful.

In the 1960s, the ropeway was used for much more peaceful purposes. A gazebo was added, and the Sahl family went on Sunday excursions to the ropeway. Here they spent the day making rope from self-tied yarn. H.P. Sahl had pensioners to help him cut off knots and tie the straw sickles together. He often said that when he was old and finished with the shop, he would not make recycled ropes. Unfortunately, he never got around to it.

Skjern Reberbane

But now hemp ropes are once again being made on the ropeway. The first order was Troense Rebslageri "Rebslager Ole Magnus" who needed shelter and labor, as "sewing rope" was to be made for the Frigate Jutland. The sewing rope is part of the ship's rigging in the following place: The rope that stiffens a ship's mast laterally is stretched down to the deck in a short pulley. The blocks in the waist are called "maidens" and the "sewing rope" is sewn into the holes in the "maidens".

Such specialized tasks are exactly what the rope butchery is suited for. Where the standardized rope factories have to give up. Another example: when the bell ringer rings the bell, he has an endless rope that runs around a roller that makes the bell rotate. This rope has to be four-stranded because it has to turn sharply around the roller, but without the small center filling "the heart". This flattens the rope and gives a better grip on the roller.

It could also be the rigging for traditional Danish dinghies or horse-drawn carriages. What coachman wouldn't want a real horsehair bridle? And what about the Danish Boy Scouts, who have banned plastic rope pulling?

In other words: If you have a "snotty" problem, come to Skjern reberbane.